Xilog Maestro Software Tutorial

Produce and the software generates all the information and manages all the machining operations necessary to produce the required object.

Siddhar Thirumoolar Life History in Tamil (Story, Tirumular Varalaru Tamil, Biography, திருமூலர் வரலாறு, குறிப்பு ). The detailed History is explained below. Ancient Tamil literature called 'Thirumanthiram' by 'Thirumoolar' Posted on the first day of the Tamil month 'Thai'. This day marks Pongal Festival an. Story book 63 Nayanmars by Kirupanandha Variyar. Thirumoolar Thirumanthiram HandBooks. Send Thirumoolar Thirumandhiram tamil pdf to my mail id: mohanraj.  Thirumoolar is scholar in Tamil language and his work “Thirumanthiram” is of greatest importance in Tamil literature. His work THIRUMANTHIRAM deals with conquering mind soul and body and is the key part of Tamil Shaiva Siddhanta, THE TENTH THIRUMARAI. LIFE HISTORY OF THIRUMOOLAR A Student by name Sundaran who belongs to Madurai in Tamilnadu had undergone his studies with guru Agasthiar in Pothigai Region. Agasthiar was a Siddhar, Saint and Rishi. His contributions to Tamil literature are very huge in the field of Medicine, Sithandham, Vedhantham, and Physiology.

Thirumoolar is scholar in Tamil language and his work “Thirumanthiram” is of greatest importance in Tamil literature. His work THIRUMANTHIRAM deals with conquering mind soul and body and is the key part of Tamil Shaiva Siddhanta, THE TENTH THIRUMARAI. LIFE HISTORY OF THIRUMOOLAR A Student by name Sundaran who belongs to Madurai in Tamilnadu had undergone his studies with guru Agasthiar in Pothigai Region. Agasthiar was a Siddhar, Saint and Rishi. His contributions to Tamil literature are very huge in the field of Medicine, Sithandham, Vedhantham, and Physiology.

I'm currently employed at a company that fabricate a lot of stairs. The plans for the stairs are made by a different company and are delivered to us in DWG- or DXF-formats. In order to get the right starting point in my machine I have to tweek these files a bit but the results are varying, adding lines or circles to the sketch often make the import into Xilog Plus( my CNC software ) invert the X-value of the inserted line. The order in which I tweek the files are as follows: 1. Remove excess lines. Make sure all lines and figures are in the same layer. Insert breaking points to lines so that the software recognizes a starting point.

Move the X and Y values so that 0,0 is in the top left corner of the work piece. Import the files to Xilog plus where the program make GCODE out of it. My feeling is that in the process of tweeking the DXF-file in autocad the values somehow gets messed up but I can't figure out how or why. Sometimes it works first go, sometimes it doesn't. Best Regards // Christian. I'm currently employed at a company that fabricate a lot of stairs. The plans for the stairs are made by a different company and are delivered to us in DWG- or DXF-formats.

In order to get the right starting point in my machine I have to tweek these files a bit but the results are varying, adding lines or circles to the sketch often make the import into Xilog Plus( my CNC software ) invert the X-value of the inserted line. The order in which I tweek the files are as follows: 1. Remove excess lines. Make sure all lines and figures are in the same layer.

Insert breaking points to lines so that the software recognizes a starting point. Move the X and Y values so that 0,0 is in the top left corner of the work piece. Import the files to Xilog plus where the program make GCODE out of it. My feeling is that in the process of tweeking the DXF-file in autocad the values somehow gets messed up but I can't figure out how or why. Sometimes it works first go, sometimes it doesn't. Best Regards // Christian Hi Christina, I have same problem with machine origin (mirror xy axis).

Did you solve yours?? I'd be thankful if you can answer me. All best, Sedina.

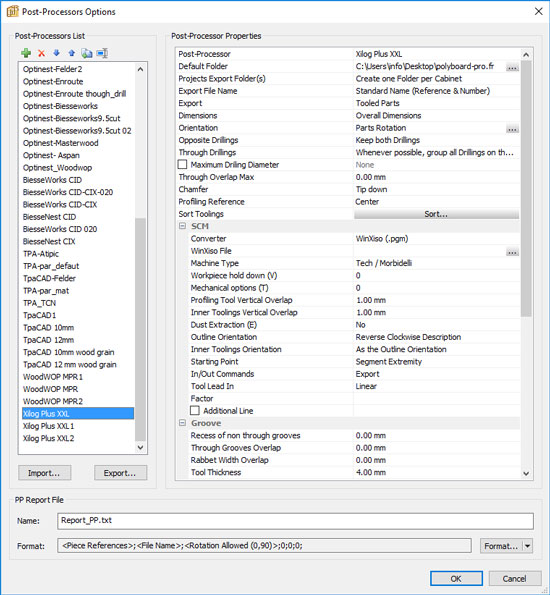

The problem are cause to a wrong conversion of the iso program file created by Aspan in the Xilog/XilogPlus format. To do this conversion, Aspan uses an utility created by SCM: WinXiso.exe. Usually Aspan has a copy of the winxiso file (and all the related dlls) in its installation folder, but as you can understand, considering all the versions of the Xilog interface, sometimes happens that this version cannot work with the Xilog used on the machine.

Kana kanum kalangal season 1 title song mp3 download. To bypass this, there are two ways: Solution 1 - applicable if you have the same Xilog/XilogPlus of the machine installed on the Aspan PC: - from the first/main window of Aspan you can execute the command 'Utility -> Technical menu -> Modify Preferences', select the 'Config. For import the configuration XILOG / XilogPlus (release Configuration > import'.

(select the folder where. Throught the Service Disk procedure of ASPAN, is possible to receive an accurate assistance on the problems encountered, without the need of a direct intervention to the user, as it allows our technicians to riprodune the working environment of the user.

For technical problems encountered during use of the program is always preferable to send a service disc from your installation of ASPAN before contacting technical assistance. The procedure is different depending on the version of the program used: (it is possible to identify the exact release of ASPAN with the menu command Help > About). Barcode configuration The BarCode Reader is supported starting from ASPAN 6.0.

The only supported BarCode type is '3 of 9'. Just make a Part program, then go to CAD and from File => Print you can print the drawing with the BarCode in it.

If you need further details: • You should first check that the font 3 of 9 is installed in your system: Start => Control panel => Fonts • You can configure the BarCode either from inside the Supervisor (utility => BarCode configuration), the CAD (File => Preferences 'BarCode configuration') or at the moment the Part Program is created (the 'BarCode configuration' button). ASCASP (ASCTASK), tool compensation for CUTS In AscAsp (AscTask) you can specify a tool compensation, appending, to the instruction. When using the cutter, this compensation is automatically changed to Depth compensation. If you do not want the automatic change and you want to apply a left or right compensation, you must act as follows: 1) edit the file c: aspan4 utl ascasp.ini using a text editor (in windows 95+ simply double click over this file) 2) nsert, as first line: UseC3withG=0 Example: UseC3withG=0 [USER_000] MakeDRW=1. 3) Save the file.